While this has its merits (eg. I don't give up at the first case of failure) after a time it becomes beating my head against a wall. Today has been an exercise in such.

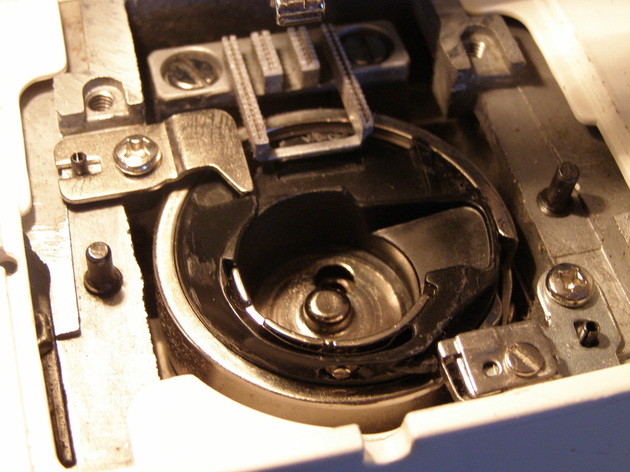

In the last 24 hours however I have broken two needles, both for the same reason. The cause of which has been the # 1 problem I've had with my machine. The bobbin holder keeps "jumping" up and breaking the needle. For the life of me I can't figure this out. I've been all over the internet, searching as generally and specifically as I could think to do.

But sometimes it's not what you think, it's not what you read, it's what you see or don't see that gives a clue to the problem.

1. Apparently I've been winding my bobbin wrong, there's a widgetmathingie on the back of my sewing machine, in the middle about where the top thread spool sews for sewing. You place your spool there. I've also been wrapping the thread wrong and I seem to have lost both spool caps. How I managed that last one I don't know, as generally I don't dare get rid of anything that comes with any machinery I buy whether I think I need it or not.

2. I've been threading the bobbin in the most bass-ackwards and wrong way possible. I'll try to paint you a picture, but literally I was lowering the needle and thread, which creates a loop, then sticking the bobbin thread in that loop. Then I'd slowly raise the needle and tug on the thread hopping I caught the bobbin thread enough. There is clearly an easier way to do this which doesn't makes sense to me, but given the mechanics of the inside of the sewing machine it works and it doesn't much matter how. I was also threading it to feed clockwise, rather than counterclockwise.

While both of those problems will cause numerous issues in your use of a sewing machine neither was the problem at hand. In fact the problem was rather simple after all was said and done, it was figuring out how it happened and why it kept happening that was a problem.

I gave it a few test turns and it seemed fine, but that had happened before so I still didn't trust it. Then I took a chance and used the pedal - I even made a video so you could see what it is supposed to look like:

So there was my little misadventure. In real life it involved a bit more profanity and exasperated sighs. And it took hours (I'd been working on this since about noon to 1 pm till now (5:15 pm).

Moral of the story ~ have patience, keep trying, but know when to step away, seek help and get a second perspective - or four!

In the comments below I'd love to know...do you have sewing machine problems? How have you gotten past them? What's your worst sewing faux pas? And make sure you join the newsletter and drop by my social media to connect with me in real time!

RSS Feed

RSS Feed